Sediment and Flammable Waste Trap Management

This guidance document is prepared by MnDOT personnel and is intended only for use on MnDOT projects, including partnership projects, and MnDOT Maintenance Operations.

MnDOT has prepared this guidance document to provide its internal procedures and requirements for work performed on MnDOT rights of way, including MnDOT-owned facilities.

This document should not be construed as a full description of all regulations pertaining to this subject matter. Contact the Regulated Materials Unit in the MnDOT Office of Environmental Stewardship for additional information or legal requirements.

Background

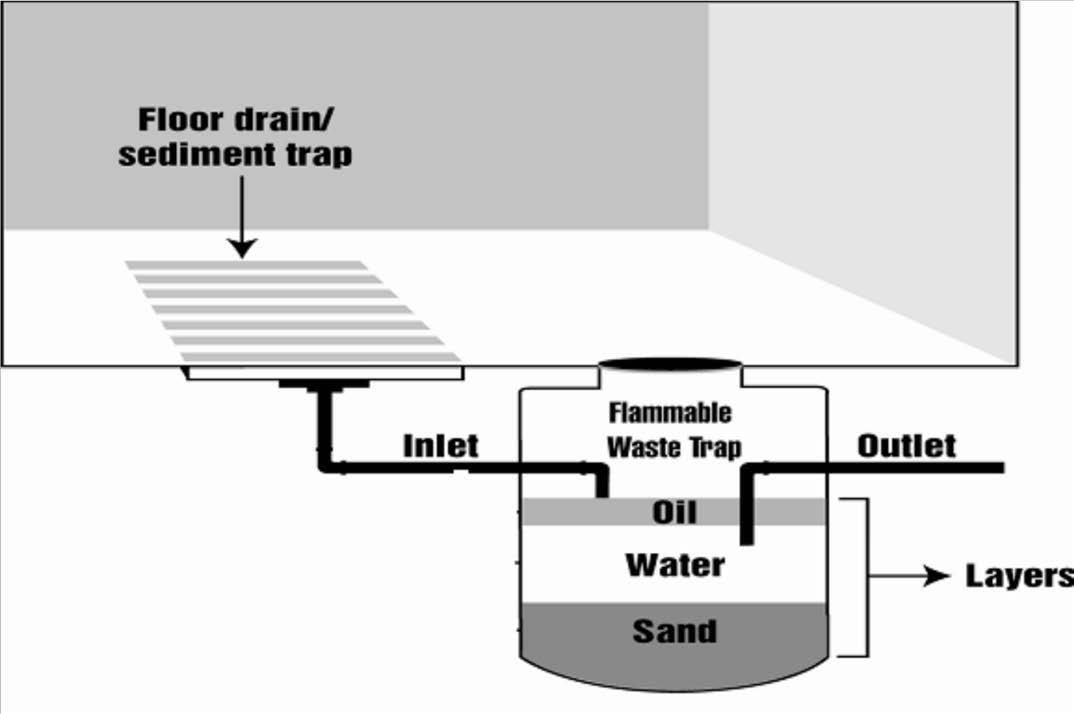

In general, the sediment trap collects wastes generated from the vehicle washing area and the flammable waste trap collects wastes from the maintenance shop area. Sediment and flammable waste traps are designed to contain solid particulates and oily wastes that are produced during maintenance and washing operations of vehicles, equipment and floors. The flammable waste trap generally has three layers (see diagram below) comprised of a top oily layer, a middle water layer and a bottom sand (solid particulate) layer.

The objective of the waste traps is to minimize the release of solid particulates and oily waste through the floor drain system to the sanitary sewer, wastewater holding tank or drain field. This is beneficial for the wastewater treatment system, the environment and also prevents illegal discharges of these waste materials. In order for the traps to operate efficiently, it is critical to clean the traps periodically to ensure that adequate capacity is available in the traps to contain waste materials. This guidance document describes the procedure to clean the traps and how to properly manage the waste materials collected during the cleaning process.

General Requirements

The following recommendations should help reduce the amount of chemicals released on the maintenance shop floor that ultimately ends up in the waste traps.

Good general housekeeping

- Clean spills immediately to prevent chemicals from entering waste traps.

- Keep containers sealed when not in use to prevent spills.

- Only wash engines if absolutely necessary to reduce generation of oily wastes and other contaminants

- .Sweep up sand and other waste.

- Use screens in the drain to prevent solids from reaching the waste trap.

- Use drip pans under equipment being serviced to collect fluids.

- Have necessary spill response equipment in place to quickly clean up and contain spills.

Cleaning out the sediment trap periodically will prevent sediment from flowing into the flammable waste trap. Note: Typically, drainage from the sediment trap flows into the flammable waste trap which then flows into the sanitary sewer or wastewater holding tank.

Avoid dumping liquid wastes (solvents, oils, etc.) into floor drains. This is an illegal disposal practice and compromises the wastewater drainage system from functioning properly.

Waste Trap Cleaning Procedure

The following guidance for cleaning waste traps and managing the waste materials removed from the traps assumes that wastes entering the traps are from routine maintenance procedures. Notify your District Waste Management Coordinator if a gasoline, solvent, herbicide or any other chemical spill has entered the floor drain system. In the event of a spill, OES personnel will collect samples from the waste trap for analysis and determine how to properly manage the waste material.

Sediment Trap

The sediment traps in the vehicle wash bays must be cleaned periodically. Once the trap becomes full of sediment, the trap will no longer function properly and sediment will begin to pass through the trap. The following procedure should be used to clean the sediment trap:

- Remove any oils using sorbent pads that are hydrophobic (will not absorb water).

- Drain water from the trap by pump or bucket. Temporarily store water in clean container. Return the water to the trap after the cleaning procedure is complete.

- Remove sand/sediment from trap using shovel and/or vacuum equipment.

Flammable Waste Trap

The oil layer in upper portion of the flammable waste trap must be removed at least once a year. This is necessary to prevent the top oil layer from reaching a thickness where oils and other potential chemicals could pass through the trap and into the sanitary sewer. Whenever removing the oil layer, check how much sediment has accumulated in the bottom of the trap. Excessive sediment should also be removed to ensure that the trap functions properly. The following procedure should be used to remove the oil layer and to clean the trap:

- Place sorbent pads that are hydrophobic (will not absorb water) in the trap to collect the oil layer.

- The middle water layer can be removed and temporarily stored in clean drums. After the sediment has been removed from the flammable waste trap, the water can be returned to the trap.

- Remove sand from tank using shovels and/or vacuum equipment.

If there are any additional layers or any inconsistency with the above description of the flammable waste trap, discontinue the cleaning operation and notify your District Waste Management Coordinator. The Office of Environmental Stewardship will determine the composition of the waste material through sampling and laboratory analysis.

Storage

The used sorbent pads may be stored with other oily wastes such as rags and other sorbent materials. The sand or sediment is considered an industrial waste and must be stored out of the outside elements. This would be in an area with a roof and the ground must be covered or on pavement.

Disposal of Waste Materials

Following are disposal and recycling alternatives for the various waste materials collected during sediment and flammable waste trap cleaning.

Sediment or sand collected from the sediment or flammable waste trap

- MPCA Permitted Line Sanitary Landfill or Industrial Landfill – Sediment can be disposed once all water has been removed from the sediment. This can done by letting the sand and water separate then the water can be pumped off or run off. Contact the landfill to make disposal arrangements.

- Asphalt Plant – Sediment can be reused at a MnDOT approved asphalt plant once all water has been removed from the sediment. The asphalt plant must be contacted and arrangements made prior to use. Contact OES to request an environmental audit for any asphalt plant not already approved for use.

Oil sorbents or oil collected from flammable waste trap

- Oil sorbents collected from the trap may be combined and recycled with other burnable oily wastes by a MnDOT approved vendor.

- Contracting with a septic service.

MnDOT facilities can contract with a septic service to clean sediment and flammable waste traps and to transport the waste for disposal at a wastewater treatment plant.

Contact OES to request an environmental audit for any asphalt plant not already approved for use.

Transportation

The waste trap sediment can be transported in MnDOT trucks, roll-off containers or drums. The load must be properly covered to prevent loss during transport. Check with the disposal or recycling facility to determine any additional requirements for dropping off the waste.

Recordkeeping

Facilities generating and receiving waste materials from sediment and flammable waste traps must maintain disposal or recycling records. The record must contain the following information: description of waste material; name and address of the facility shipped from (MnDOT facility); name and address of the facility shipped to (facility accepting the waste for recycling or disposal); quantity shipped; dates of shipment and acceptance at recycling or disposal facility. (See link for log template under “Waste Handling”).

Records include: manifests, scale tickets, or invoices at MnDOT facility for a minimum of three years. After three years, the records can be sent to OES for permanent storage.