NRRA Newsletter: February 2019

Stabilized Full Depth Reclamation Test Sections

By Michael Vrtis, Research Project Engineer, MnDOT

This summary will highlight the field performance and lessons learned from Stabilized Full Depth Reclamation (SFDR) test sections after 10 years of performance at MnROAD.

Existing Test Sections

To properly show the benefit of the SFDR sections at MnROAD the existing pavement structure and condition must be understood. Test cells 2, 3, 4, and 15 were originally constructed in 1993. By 2007, significant distress had developed within the cells, as shown in Figure 1.

|

Figure 1. Cell 2 in 2007 prior to SFDR (similar conditions in Cell 3, 4, & 15) |

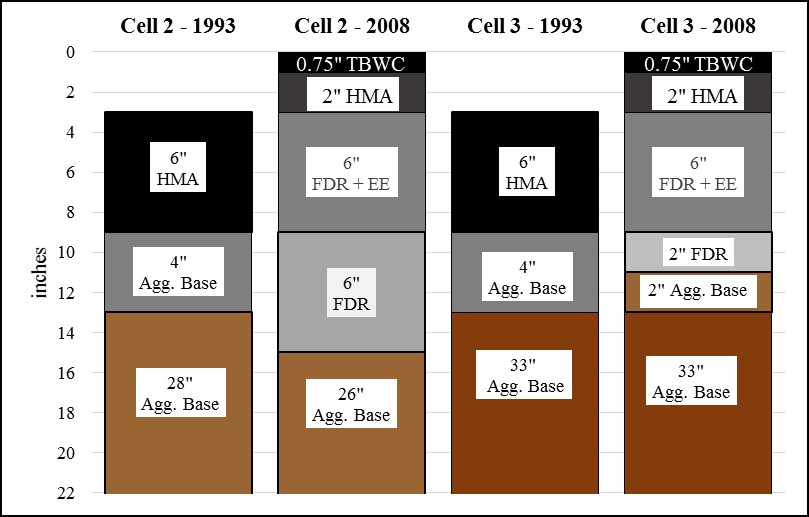

Figure 2 shows the existing (1993) and the rehabilitated (2008) pavement structures for each cell. Cells 2 and 3 were designed according to MnDOT’s Bituminous Aggregate Base procedure, the standard at that time. Cell 2 consisted of 6 inches of HMA over 4 inches of MnDOT Class 6 base over 28 inches of MnDOT Class 4. Cell 3 also consisted of 6 inches of HMA over 4 inches of Class 6 base over 33 inches of MnDOT Class 3 base. Cell 4, comprised of 9 inches of HMA constructed directly on the prepared clay loam subgrade (AASHTO A-6), was designed according to MnDOT's Full-Depth Bituminous design procedure.

Study Objective: Cells 2, 3, and 4 were selected for SFDR because the structure of the existing sections provided an opportunity to exhibit the ability of the SFDR to eliminate the existing cracking patterns and allowed for testing of different SFDR blends for each cell. The project was initiated by SemMaterials under a special partnership to investigate SFDR with engineered asphalt emulsion. SemMaterials funded the design and construction while MnDOT was responsible for performance monitoring and reporting. In addition to evaluating the long-term performance of SFDR, the objective of these test sections was to determine the optimal percentage blend of HMA and aggregate base for county roads with medium to heavy traffic.

Three blends of HMA and aggregate base were constructed: 50/50 (Cell 2), 75/25 (Cell 3), and 100/0 (Cell 4). The existing structure of Cell 4 did not have any aggregate base, thus the SFDR was done with the clay loam (AASHTO A-6) subgrade. The three test cells were compared to Cell 15, a full-depth design section similar to Cell 4, which received a conventional 3 inch asphalt overlay to restore ride and improve structure.

|

Figure 2. Cross sections of cells before and after SFDR |

SFDR Structure

The sections were designed for a 5-year, cumulative design ESALs of 3.5 million. It can be seen in Figure 2 that the final elevation of all cells increased 3 inches. Cell 2 (50/50) had 12 inches reclaimed (6 inches of HMA and 6 inches of base). Cell 3 (75/25) had 8 inches reclaimed (6 inches of HMA and 2 inches of base). The top 6 inches of Cells 2 and 3 were treated with engineered emulsion (4.0% and 3.0% design emulsion, respectively).

In Cell 4 (100/0), 8 inches of the existing HMA was milled and set aside for later use. The remaining 1.0 inch of HMA was reclaimed with 8 inches of clay and 16% fly ash; thus creating a 9 inch fly ash stabilized layer. Millings were then placed on the stabilized layer and reclaimed with 0.75% engineered emulsion (0.5% design constructed at 0.75% due to construction equipment limitations).

HMA was placed over all stabilized layers. Cell 2 (50/50) and Cell 3 (75/25) had 0.75 inch of Novachip (Ultra-Thin Bonded Wearing Course) as the surface layer placed over 2.0 inches of PG 64-34 HMA, whereas Cell 4 (100/0) had 1.0 inch of a fine dense-graded bonded wearing course over 2.0 inches of PG 64-34 HMA.

The cells were instrumented with asphalt strain gauges, earth pressure cells, moisture gauges, and thermocouples at critical locations through the pavement structure to provide insights into structural response due to traffic and environmental conditions. A link to the analysis from the instrumentation is provided at the end of this document.

Performance Summary

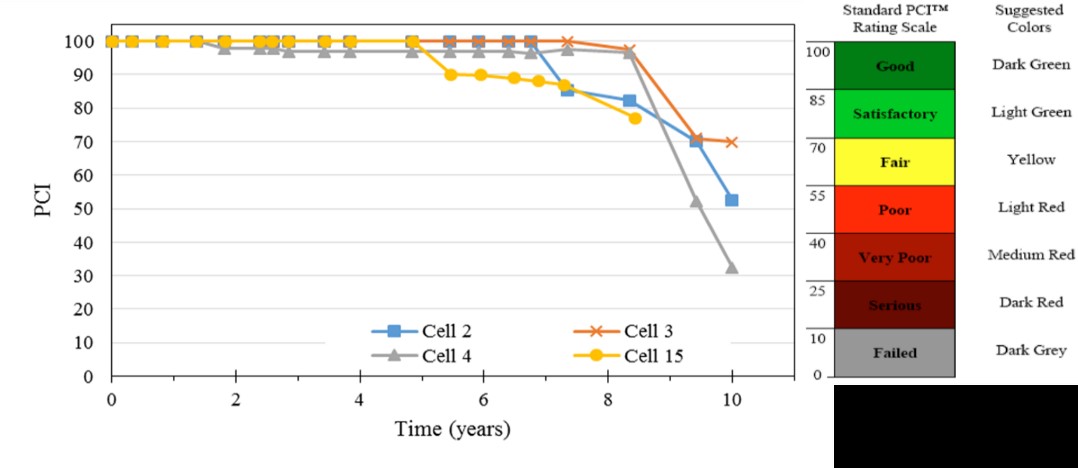

All three SFDR cells have exceeded their 5-year design life with no major rehabilitation or resurfacing required. The design ESALs were greatly exceeded with the driving lane having withstood over 8.5 million ESALs during that time. It can be seen in Figure 3 that all cells had a Pavement Condition Index (PCI) in the “Good” range (above 85) after 5 years in service. PCI is used as a summary index of pavement surface distresses that were recorded following LTPP Distress Identification Manual; it has a scale of 0 to 100, with 100 representing a pavement with no distress. Cell 15 (Control) was the first cell to have PCI drop out of “Good” and required a maintenance treatment in 2017. All SFDR cells stayed “Good” until after 7 years. The PCI values of the cells have dropped substantially from years 8 through 10, primarily due to cracking in the wheelpaths, as shown in the image. The wheelpath cracking observed was atypical as it started as raveling and progressed into an interconnected wheelpath cracking area (classified as fatigue). Cores will be taken in spring 2019 to determine the extent of the cracking and to determine a repair strategy. At this time, it is believed that the SFDR structure of these cells is still intact; therefore a mill and inlay of the crack HMA surface layers may likely be the recommended strategy. All sections are still in place and providing sufficient ride, although distresses are developing as evidenced by the precipitous drop in PCI over the last 2 years.

|

|

Figure 3. PCI plot and wheelpath cracking in Cell 2 |

|

Rutting did not have much of an impact on the PCI values as rutting values for all cells were below the conventional rutting threshold of 12.5 mm, indicating that sufficient structure was provided by the stabilized layers to withstand the interstate traffic loading. Cell 4 currently has visible rutting with values around 10 mm.

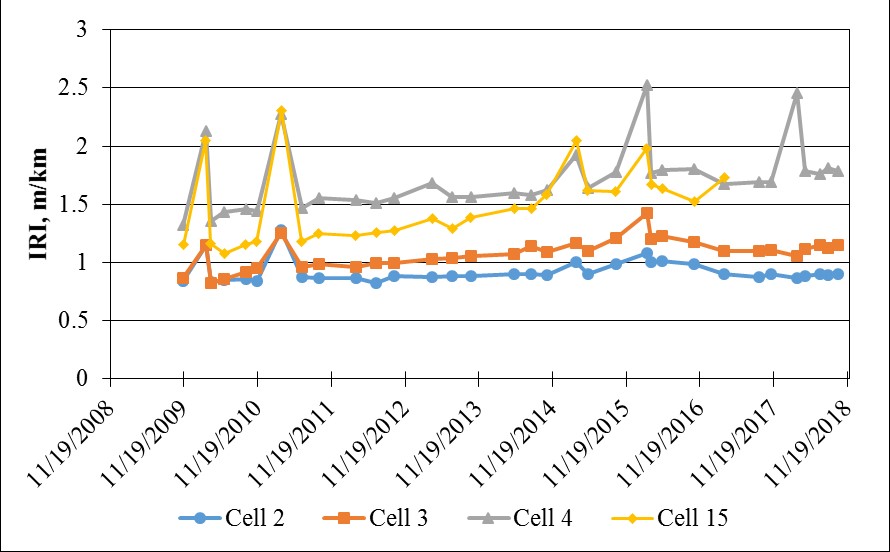

The ride performance is presented in Figure 4. The plot shown displays the average IRI from both wheelpaths of the driving lane. It can be seen that Cell 4 had the highest initial IRI and also increased the most over the last 10 years of traffic. Some of the roughness may be attributed to the patched areas shown in the image below. These patched areas were core locations. Moisture penetrated the core holes and heaving occurred. The area surrounding was saw cut for forensic investigation and square patches were placed. It can be seen in the image that localized distress has occurred surrounding the patches. This emphasizes the importance of sealing the pavement from moisture especially with heave susceptible soils. Cells 4 and 15 have large spikes in their IRI values that is due to seasonal variability; this is a further validation of MnDOT’s Bituminous Aggregate Base procedure as Cells 2 and 3 do not show spikes of the same magnitude. Further research is being conducted on examining the trends in IRI data with respect to seasonal variability and traffic.

|

|

Figure 4. IRI plot and patching/ forensics in Cell 4 |

|

Key Findings

The key findings from the SFDR research effort are summarized below:

- SFDR successfully removed the cracking distress pattern of the existing roadway and provided a consistent structure to withstand interstate traffic for double its anticipated design life from 5 to 10 years (designed for 3.5 million ESALs; has withstood over 8.5 million ESALs). Properly designed SFDR can be well suited for high volume trunk highways and interstates.

- The test sections at MnROAD validated that SFDR structures are a viable solution to rehabilitate a severely cracked asphalt roadway providing it has adequate base and consistent materials for support.

- Instrumentation within the pavement structure and falling weight deflectometer testing provided insight into strain distribution and showed that the structural contribution of SFDR layers is more similar to a HMA layer than a granular layer. To achieve similar performance, care should be taken in engineering the SFDR modifiers for traffic and environmental loads.

- SFDR over a granular base (Cell 2-3) provided a more stable structure than the full depth asphalt (Cell 4) and conventional overlay (Cell 15 - Control).

- The importance of keeping moisture out of the pavement structure was highlighted by the increased IRI resulting from the patch areas in Cell 4.

- The structure provided by SFDR can be used continuously with only surface layers requiring removal and replacement if action is taken before the stabilized layers deteriorate.

Implementation Plan/Action

- Used as a case study for LRRB – Base Stabilization Guidance and Additive Selection for Pavement Design and Rehab

- Minimum thickness for HMA layer over SFDR reduced to 2 inches based on the performance of these cells

Additional Resources

Where are They Now: Julie Vandenbossche

MnROAD has been a classroom and research facility for many graduate students over the years. One of the stand-outs has been Julie Vandenbossche, associate professor at the Swanson School of Engineering at Pittsburgh University. She did her Ph.D. research at MnDOT, and the facility itself was “the whole reason I came to Minnesota,” she said.

After getting her B.A. and M.S. at Michigan State, Vandenbossche enrolled in the University of Minnesota and eventually ended up at MnROAD. Vandenbossche’s Ph.D. work involved warping and curling and included measuring the shape of the slabs in the first concrete pavement cells constructed at MnROAD.

Whitetopping

She also worked for MnDOT for five years and her first project included instrumenting a road being paved in Olmstead County. She used thermocouples to monitor strength gain in the concrete. The purpose of this was to better understand construction issues that were occurring. Her work building and monitoring white topped cells at MnROAD has had national ramifications. It “had a huge effect on getting those types of overlays adopted and accepted around the country,” she said.

|

| Vandenbossche with Matt Zeller, Maria Masten and Len Palek at the 2017 Pavement Conference at MnROAD |

Buy In

One of her mentors at MnROAD was Dave Rettner, now president of American Engineering Testing (and NRRA associate member). From Rettner, she learned the importance of working with industry. He was with MnDOT at the time and because he worked out in the districts, he had a wealth of contacts with private contractors he could pull into research projects at MnROAD. Getting that buy in from contractors became a very important part of Vandenbossche’s education. “Absolutely everything I do research-wise, I try to use that approach,” she said.

Data

The data from MnROAD continues to be, for Vandenbossche, the gift that keeps on giving. “The majority of projects I have worked on since then, even here at Pitt, have used MnROAD data in one form or another,” she said. She is especially fond of the data from some of the earliest test sections. Many of these cells have dramatically exceeded their performance expectations, and she says the quality of the data from those sections is very high. Three things contribute to the quality of this data, says Vandenbossche:

- Experimental design

- Sufficient cell length to establish an average

- Quality, quantity and accessibility of the data

Now, 20 years later, she is a huge advocate for MnROAD and hopes it continues its commitment to high quality data. “The success I have had since I have left can be attributed back to MnDOT with respect to trying to get stake holders involved throughout the process so that my research initiatives are driven by actual needs and the solutions provided are implementable.” said Vandenbossche.

Knowledge Books: A System for Capturing Expertise

We all know someone like Gordy. We may even know more than one. In the case of MnDOT, he’s the guy who knows almost everything about a topic, often learning it through decades of experience. And he’s retiring--soon.

Our Gordy is Gordy Bruhn and he is MnDOT’s concrete specialist and senior engineering specialist. He was the first to go through a process called Knowledge Book, an attempt to capture his expertise so that it can be accessed by others, even after he retires.

So what is a Knowledge Book? It’s both a document of a sort as well as a process. The process is involved, and takes some time, but it does, as much as possible, create a complete picture of a person’s expertise.

Let’s examine the document. Bruhn’s book is almost complete, and it is in the form of a PowerPoint file. It is an interactive document involving charts, photos, videos and more; as such it is a very large document, currently weighing in at more than 300 megabytes and 250 slides.

| Gordy Bruhn recently did a quick demo of his Knowledge Book at an Everyday Counts Peer Exchange. Here's Gordy explaining it. |

The Process

First, the fact that there is a process for true knowledge capture is in itself remarkable. For years, HR and Knowledge Management experts have talked about the need to capture the knowledge of retiring Baby Boomers, but there was a preponderance of talk and not a lot done. Mike Leegard, MnDOT’s principle investigator for this project, found a process called MASK (Method of Analyzing and Structuring Knowledge) that seemed to fit the bill.

MASK came out of a project in France where they were trying to capture the knowledge of nuclear power technicians. Then it moved to the nuclear weapon industry. Leegard came across it during a presentation by Nanaka Mura from Kraft Foods at TRB. He contacted the folks in France that run MASK and hired Jef Tendron, an aeronautical engineer by training and a recognized expert in the process.

In order to contract with Tendron, a French national living in Thailand and being paid in Euros, Leegard needed some help. He had a relationship with Scott Taylor, a professor at South Central College in North Mankato, MN, and they worked together on the contract. South Central handled all the ins and outs of the contracting process.

The first step in the MASK process involved mapping out the critical knowledge. This is what Taylor calls deep knowledge or “capturing the art of decision making in complex circumstances.” Tendron flew in and met Bruhn and the original scoping interview took 60-90 minutes.

After that, the hard work begins. A series of interviews, both face-to-face and through Skype, began between the two. Bruhn estimates that maybe 20 hours of face-to-face and 20 hours of Skype interviews took place before Tendron went to work on translating the interviews into the Knowledge Book.

Taylor says the first Knowledge Book took about a year to reach an almost-completed stage. He estimates that it could take about 6 months if you wanted to push it.

Once it’s complete, it’s sent for edits and approval to the author. In this case, Bruhn is the author and final approver. Once complete, it will be locked down. That means only Bruhn will be able to change, or add to, the Knowledge Book. When he retires, he will choose a colleague at MnDOT to oversee, and carefully edit, his Knowledge Book.

Leegard says this project is unique for a couple of reasons. First, it will be the first publicly accessible Knowledge Book ever. The ones done for the French nuclear energy industry were, understandably, not public. Kraft’s books too were full of trade secrets. Bruhn’s book will eventually be out on the Web.

Because of its size, the Knowledge Book Powerpoint file is a problem. It is not ADA accessible, which is a MnDOT requirement. Furthermore, it’s so big that accessing it via a tablet or smartphone—something you would want to do out on a construction site—wouldn’t work.

Taylor explains that a retired professor at South Central will be converting Bruhn’s book into a program called Articulate Storyline. This will make it ADA compliant and the content will then be streamed, rather than downloaded, making it much more useful for mobile users. Bruhn’s best guess is that the actual book will be available in two months.

Leegard has been very encouraged by the process and the results. “When people used to talk about capturing knowledge, I never expected there to be this organized methodology. I think we all looked at it like it was smoke and mirrors. The thing I didn’t expect is there is actually a system,” he said.

The one risk he mentioned is that, right now, there are only seven people in the world who do what Tendron does—the interviewing and analysis and synthesis of the knowledge. And only three of them speak English, so the expertise to create these books is scarce.

Tendron told Leegard during this process “engineers make the best MASK knowledge book writers because most of them are very technical. Beyond that, he says, you just have to be very inquisitive.”

Research Pays Off March

Our webinar series on March 19, (10 a.m.) will examine research about Determining Pavement Design Criteria for Large Stone Subbase Materials. Bora Cetin, Assistant Professor in the Geotechnical and Geoenvironmental Engineering Area in the Department of Civil, Construction and Environmental Engineering at Iowa State University will be presenting.

Welcome to New Members

Welcome to our new alliance members Iowa Department of Transportation and National Asphalt Pavement Association.

2019 NRRA Pavement Workshop--Registration is Open

Please plan to attend this year's NRRA Pavement Workshop. The latest news is:

- We have an App for the workshop.

- We've added an extra day. May 21 will showcase "BIM for Pavements . . . Asset Management, Planning, Design and Construction."